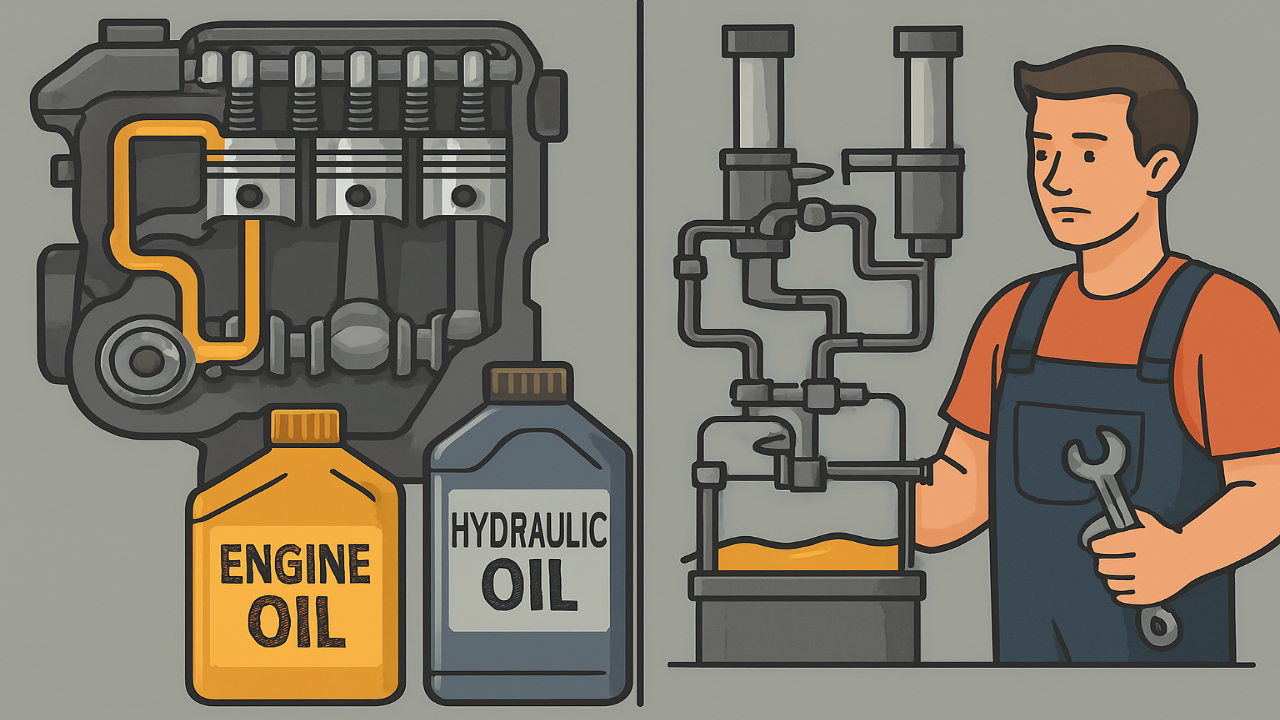

This guide breaks down engine oil vs hydraulic oil completely. We'll cover motor oil differences, hydraulic fluid applications, composition breakdowns, and real-world substitution risks.

Both lubricate machinery, but they shine in totally different roles. Key differences lie in composition, viscosity, additives, and performance under pressure. Substitution? Sometimes possible in emergencies, but risky for modern equipment.

What is Engine Oil?

Engine oil, also called motor oil, keeps your internal combustion engine running smooth. It slashes friction between pistons, bearings, valves, and camshafts.

Types breakdown:

- Conventional: Cheap, good for older engines. Made from crude oil. Changes every 3,000-5,000 miles.

- Synthetic: Premium choice. Lasts longer, better in extreme temps. Changes every 10,000-15,000 miles.

- Semi-synthetic: Budget-friendly hybrid. Think SAE 15W-50 for trucks or SAE 5W-30 for cars.

Four critical jobs:

- Lubricates moving parts

- Cools hot components

- Cleans combustion sludge

- Fights rust

Engine oil thrives in high-heat environments up to 250°F+. Oil gallery pressure: 40-80 PSI at operating temp.

Common uses: Cars, motorcycles, generators, lawnmowers, diesel trucks, small aircraft engines.

What is motor oil made of? 70-90% base oils (mineral or synthetic) plus additives:

- Detergents (calcium/magnesium sulfonates): 8-12%

- Dispersants (polyisobutylene succinimide): 5-10%

- Anti-wear ZDDP (zinc dialkyldithiophosphate): 800-1,500 ppm

- Viscosity improvers (polymethacrylate): 5-10%

- Anti-oxidants (hindered phenols): 1-2%

- Anti-foam (silicone): 10 ppm

- Pour point depressants: 0.5-1%

Pro tips:

- Change every 5,000-10,000 miles

- Check dipstick weekly

- Oil pressure drops below 20 PSI = stop engine

- API ratings: SN/SP (gasoline), CK-4/FA-4 (diesel)

Visual tip: Embed a diagram of engine components here, showing oil flow from pan to pistons via pump.

What is Hydraulic Oil?

Hydraulic oil, or hydraulic fluid, powers your equipment through pressure. It transmits force in sealed systems - not just lubrication. Think of it as the "blood" of hydraulic circuits.

Types breakdown:

- Mineral-based: Most common, affordable (ISO VG 32, 46, 68). DIN 51524 Part 2 (HLP).

- Synthetic: Extreme temps or long life (PAO-based). ISO 11158 HM/HV.

- Biodegradable: Eco-friendly for farms/forestry (vegetable esters). ISO 15380 HEES.

Core functions:

- Transfers power efficiently (0.5% compressibility)

- Lubricates pumps/valves

- Dissipates heat

- Resists wear under 5,000+ PSI pressure

Viscosity grades and flow rates:

- VG 22: 19-25 cSt @ 40°C (jacks, cold climates)

- VG 32: 28-35 cSt @ 40°C (forklifts)

- VG 46: 41-50 cSt @ 40°C (excavators)

- VG 68: 61-74 cSt @ 40°C (hot climates)

- VG 100: 90-110 cSt @ 40°C (crushers)

Common uses: Construction excavators, forklifts, hydraulic jacks, tractor loaders, aircraft landing gear, car power brakes, factory presses.

Hydraulic fluid properties:

- Anti-foam agents (silicone/polydimethylsiloxane): 5-10 ppm

- Water separators (demulsifiers): separates 40/37/3 in 30 minutes

- Shear stability: max 10% viscosity loss after 100 hours

- Rust protection: ASTM D665 pass

- Filterability: NAS 1638 Class 9 minimum

Pro tips:

- Filter changes every 1,000 hours

- Check for milky oil (water contamination)

- Reservoir temp max 180°F

- System pressure: 2,000 PSI (gear pumps), 5,000 PSI (piston pumps)

Visual tip: Add an infographic of a hydraulic system schematic—pump, reservoir, valves, cylinders.

Key Differences Between Engine Oil and Hydraulic Oil

Spot the contrasts fast. Here's engine oil vs hydraulic oil in detail. Wrong choice costs downtime.

Composition and Additives

Engine oil:

- Heavy detergents (15%): Clean combustion soot

- Dispersants (10%): Suspend particles

- High ZDDP (1,200 ppm): Cam/bearing protection

- Anti-oxidants: 350°F thermal stability

Hydraulic oil:

- No heavy detergents (cause valve sticking)

- Anti-foam silicone (0.001%)

- Low ZDDP (500 ppm): Pump protection only

- Demulsifiers: Water separates in 30 minutes

Viscosity and Temperature Range

Engine oil: Multi-grade ratings like 10W-40. "W" = winter flow. Cold cranking: 3,500 cP max.

Hydraulic oil: Steady single-grade. ISO VG 46 = 46 cSt at 40°C. Viscosity index 95-130.

Viscosity comparison:

| Temp | Engine 10W-40 | Hydraulic VG 46 |

|---|---|---|

| -20°F | 5,000 cP | 8,000 cP |

| 100°F | 14 cSt | 46 cSt |

| 180°F | 10 cSt | 32 cSt |

Performance Characteristics

- Hydraulic oil: Near-incompressible (0.05% volume change at 3,000 PSI). Shear stable 2,000+ hours.

- Engine oil: High-temp stability (400°F flash point). Deposit control for combustion.

Compatibility and Mixing

Engine in hydraulics: Detergents foam → 40% pressure loss → cavitation

Hydraulic in engine: No detergents → sludge in 500 hours → piston scoring

| Property | Engine Oil | Hydraulic Oil |

|---|---|---|

| Additives | Detergents, dispersants, high ZDDP, anti-oxidants | Anti-foam, low ZDDP, demulsifiers, rust inhibitors |

| Viscosity | Multi-grade SAE (0W-60) | ISO VG single-grade (10-220) |

| Temp Range | -40°F to 350°F | -30°F to 200°F |

| Pressure | 100-500 PSI | 3,000-10,000 PSI |

| Flash Point | 420°F+ | 380-410°F |

| Pour Point | -40°F | -25°F |

| Density | 0.86-0.88 g/ml | 0.87-0.89 g/ml |

Engine oil vs hydraulic oil viscosity matters most in cold starts. Differences in additives between motor oil and hydraulic fluid prevent system failures. (Source: Machinery Lubrication, Noria Corp., ASTM D6158)

Similarities Between Engine Oil and Hydraulic Oil

Both often petroleum-based (mineral oils Group II/III). Both lubricate metal-to-metal contact. Both use viscosity index improvers (polymers).

Key overlaps:

- Prevent wear and corrosion

- Anti-wear chemistry (zinc/phosphorus compounds)

- Contaminated by dirt/water/heat

- Flash points 380°F+

- Density 0.86-0.89 g/ml

Similarities of hydraulic fluid and engine oil include basic lubrication properties. Common properties in lubricants like anti-rust additives. Both need regular sampling.

Can You Use Engine Oil Instead of Hydraulic Oil?

Rarely safe. Check OEM manual first.

Engine oil → Hydraulics:

- OK: Old tractors (Ford 8N: 10W-30 motor oil)

- Never: Modern piston pumps (foaming, seal erosion)

Hydraulic oil → Engine:

- Lacks detergents

- Sludge builds fast (diesels worst)

- Piston scoring, ring sticking

Real risks:

- 30% pressure loss from foaming

- Pump cavitation destroys gears

- $2,500 skid steer pump replacements reported

Emergency substitute: ISO VG 46 hydraulic in engine (drain within 100 hours max).

Always follow OEM specs. Test with oil analysis kits ($30/sample).

Substitute engine oil for hydraulic fluid? Risky - old gear only. Is motor oil safe for hydraulic systems? No for modern equipment.

Pros and Cons of Each Oil Type

| Type | Pros | Cons |

|---|---|---|

| Engine Oil | Versatile heat protection (350°F) Cheap ($5/qt) Excellent cleaning Widely available | Foams under pressure Poor shear stability Detergents clog valves |

| Hydraulic Oil | Superior power transmission (10K PSI) Anti-foam/shear stable Water separating High pressure safe | Weaker extreme heat (200°F max) Specialty = pricier ($10-20/qt) No combustion cleaning |

Applications and Real-World Examples

Engine oil applications:

- Cars/trucks: SAE 5W-30 daily drivers

- Diesel semis: 15W-40 heavy-duty

- Lawn mowers: SAE 30 straight-grade

Hydraulic oil applications:

- Excavators: ISO VG 46 anti-wear

- Forklifts: VG 32 fast cycle

- Hydraulic jacks: VG 22 thin flow

- Tractors: Universal tractor fluid (UTF)

How to choose:

- Match OEM specs

- Operating temp: Cold = low VG, Hot = high VG

- Pressure rating: 3,000+ PSI = anti-wear hydraulic

Best oil for hydraulic jacks? ISO VG 22-32. Engine oil in construction equipment? Only if manual specifies.

Case study: John Deere tractor owners report 2x pump life (3,200 vs 1,500 hours) using correct hydraulic oil.

Conclusion

Engine oil vs hydraulic oil boils down to specialized roles. Engines need heat fighters and cleaners. Hydraulics demand pressure stability and anti-foam. Wrong choice means costly downtime, seized pumps, or sludged motors.

Pick right, save thousands. Always check equipment manuals, labels, and consult pros. Oil analysis ($30) beats guesswork.

Common FAQ's

Foaming starts immediately. Viscosity drops 20-30%. Seals swell or leak. Heat builds, pumps cavitate. Fix: Full flush, new filters. Cost: $200-500.

No. Transmission fluid has friction modifiers for clutches. Hydraulic pure power transfer. Some ATF works in old hydraulics.