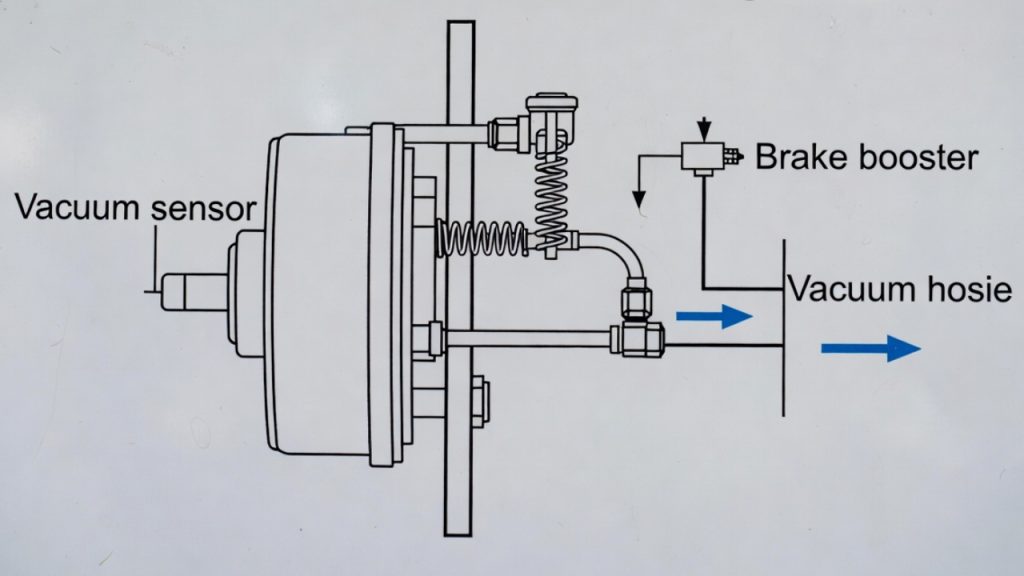

The brake vacuum sensor, also called the brake booster pressure sensor or vacuum pressure sensor, is a very important part in modern car brake systems.

This sensor always checks the vacuum level inside the brake booster. It changes the vacuum into an electric signal. Most times the signal is analog voltage. The signal goes to the engine control module (ECM), powertrain control module (PCM), or anti-lock brake system (ABS) module.

The sensor gives live information about booster vacuum pressure. This helps the car computer keep good power brake help. It turns on extra electric vacuum pumps when needed. It also works with engine start/stop systems. It makes sure electronic stability control (ESC) and ABS work right.

In old gasoline engines, vacuum comes straight from the intake manifold. But in many new cars - like diesel, hybrid, turbo GDI engines, and cars with cylinder shut-off - an extra electric vacuum pump is used. This pump gives steady vacuum all the time. It works best when engine load is low or when the engine is off.

If the brake vacuum sensor or its signal goes bad, brake pedal feel gets wrong. It can set OBD codes like P0555 to P0559. Warning lights come on. In bad cases, brake power drops. Knowing how the sensor works, what signal it should give, how the waveform looks, how to check it, and common problems is very important for correct fix and safe driving.

How Brake Vacuum Systems Changed

Brake air pull changed a lot. In 1950, power brakes start. Use engine air pull to help push. No sensor. In 1990 and 2000, cars get smart. OBD-II comes. Sensors check air pull. For good gas use.

Safe brakes like ABS. Now in 2026, electric cars are many. Use electric pumps. Engines stop a lot for stop start. Sensor keeps air pull ready. Bad sensor stops features. Brakes feel like no help. Checks must be new way. Old checks not good.

What Is a Brake Vacuum Sensor Signal?

Sensor is piezo type or MEMS type. It checks air pull in booster vs outside air. Like small air checker. It changes air pull to power signal. Most 0 to 5 volts. Some new are digital for fast info.

How it acts:

- Strong air pull at engine rest: Low volts. Like -50 to -80 kPa. Or -400 mbar or -5.8 psi.

- Push brakes: Air pull drops. Signal changes.

- No brakes: It matches engine air pull.

Some cars have digital signals. Analog is common. It watches air pull health. No good signal, computer can not fix. Gets codes. Weak brakes.

Normal Brake Vacuum Sensor Signal Values & Wave Form

Values change by car. Here is main info:

- Engine rest, no brake: 15-22 inHg air pull. Or -400 mbar. Volts 0.5-4.5. Some 4V good. 7V bad.

- Key on, engine off: No air pull. High volts like 5V.

- When brake: Volts change down smooth.

On scan tool or scope:

- At rest: Straight line. No move.

- Pump brakes: Signal changes smooth.

- Electric pump on: See steps up.

- No jumps or flat. That is bad.

Real wave forms: Steady at rest. Smooth move when air changes. Jump wave means sensor bad or leak. Check with OBD scan for live info. Or use scope on pin. Smooth wave is good.

Like in Chevy, 4V at rest with air pull. Stuck at 0V or 5V is low or high problem. Bad wave can be flat no change. Or noise jumps.

Bad wave: Flat line no change with brake push. Or spikes from wire bad.

Signs of Bad Brake Vacuum Sensor Signal

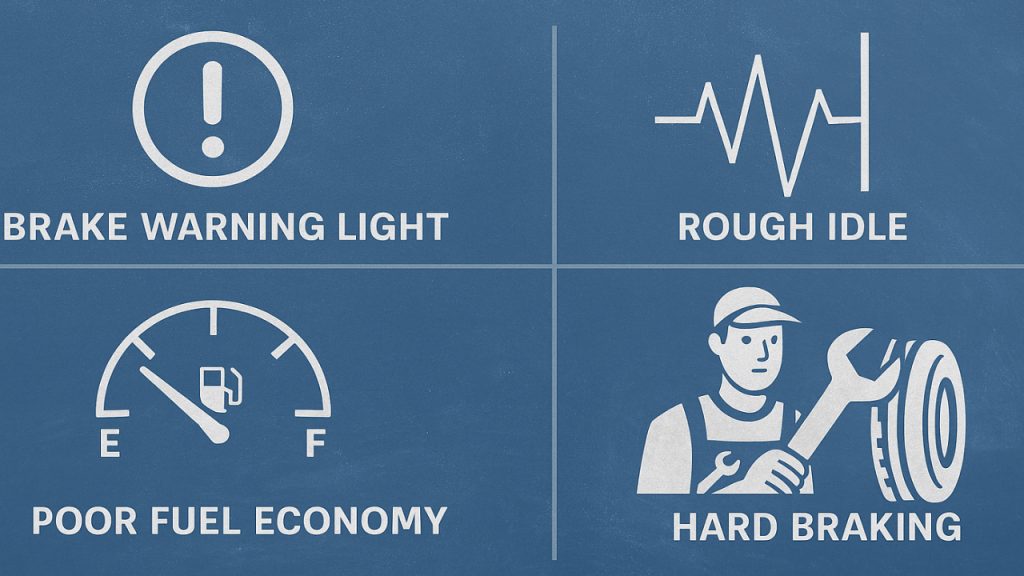

See these early:

- Hard brake pedal. Common. No help makes stop hard.

- Brake light on. Check engine light. Or low brake power note.

- Brakes slow. Long stop way. Crash risk up.

- Stop start fails. Common in BMW, MINI, VW. No smooth start.

- Engine stops or rough when brake. From air leak change fuel mix.

- Hiss sound under dash on pedal push.

- Codes: P0555 no signal. P0556 range bad. P0557 low. P0558 high. P0559 on off.

- Slow brake feel. No quick stop.

Do not skip hard pedal. Safe brakes go down fast. Check now to stop crash.

Common Reasons for Brake Vacuum Sensor Signal Problems

What goes bad:

- Sensor breaks inside. Moves wrong or stops change with air pull. Old age, hot, dirt.

- Air leaks. Bad hoses crack. Check valve bad. Booster tear.

- Wire problems. Open line. Short to ground. Loose plug.

- Low engine air pull. Or electric pump dead. In hybrid common.

- Other: MAP sensor not match. ABS bad. PCM fault.

- Sensor dirty from brake fluid leak or road dirt.

- Wet place makes wire rust.

Leaks and bad sensors most. Wet air hurts wires.

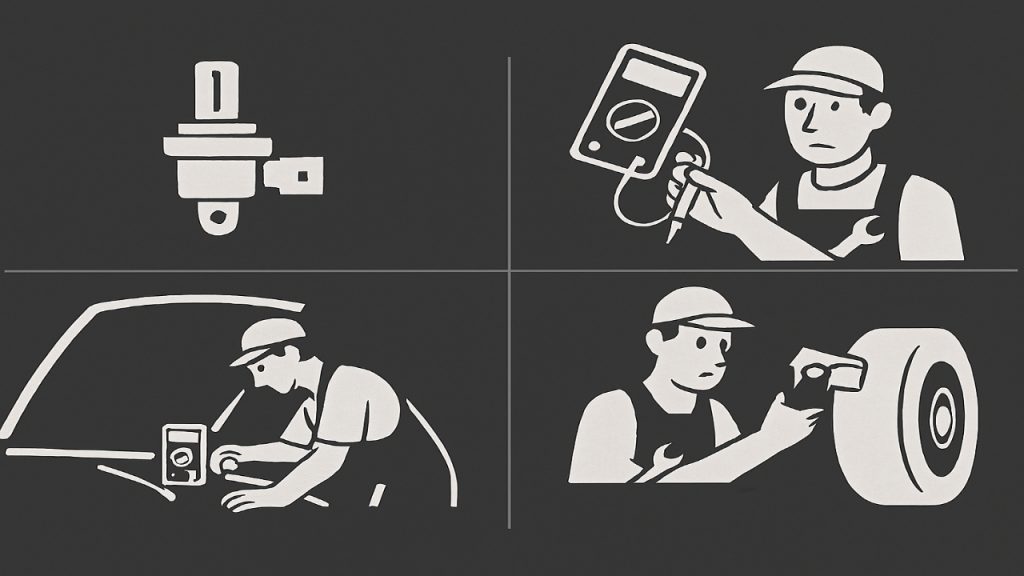

How to Check Brake Vacuum Sensor Signal Problems Step by Step

Safe first: Park flat. Safe place. Use gloves. Eye cover.

- Step 1: Scan codes. Use OBD-II tool. Look for P055x codes.

- Step 2: Look check. Find sensor on booster or line. Check hoses, plugs, leaks. See cracks or wet.

- Step 3: Watch live info. Key on engine run. See signal no pedal vs push.

- Step 4: Engine off test. Pump pedal lots. Use up air pull. Start engine. Pedal drop if air builds.

- Step 5: Put air pull. Use hand pump on line. See signal change on tool.

- Step 6: Match to MAP sensor. Throttle shut, they close same. Big diff means leak or bad.

- Step 7: Check wires. Use meter for line good, shorts, opens. 5V from computer.

- Step 8: Test electric pump. Hear run. Check fuse if no.

- Step 9: Check booster. Pump pedal engine off. Hold pedal. Start engine. Feel pedal move down.

- Step 10: Smoke test for leaks. Use smoke machine to see air leaks.

Tools: OBD tool, meter, air pump, gauge, scope if hard. Codes not go? Check deep.

How to Test & Change the Brake Vacuum Sensor

Test first to save cash:

- Pull plug off sensor. Check 5V from computer. Ground good.

- Put air pull with pump. Signal change smooth. No jumps.

- Check ohms if book says. Changes by car.

- No change or wrong? Sensor bad.

Change steps. See book for your car:

- Pull battery wire. No codes or shock.

- Pull plug slow.

- Take old sensor. Screws or clips. May let air out line.

- Put new. Tight right. No too much.

- Put back all. Battery on.

Cost: 50 to 300 bucks. Part and work. Good parts last long.

After: Clear codes with tool. May need learn drive. Test drive. Check pedal and lights. In VW, sensor with hose. Change all. Safe: No drive if brakes bad. Use jack safe.

OBD Codes & Fixes

Table with codes:

| Code | What It Means | How to Fix |

|---|---|---|

| P0555 | No signal or line | Check wires, sensor power ground |

| P0556 | Range or work bad | Check sensor, wires, air leaks |

| P0557 | Line low | Short to ground, bad sensor |

| P0558 | Line high | Open line, sensor wrong |

| P0559 | On off | Wire bad, loose plug |

| P0171 | Too lean system | Air leak from booster |

| P0300 | Random misfire | From vacuum leak |

Other: BMW 002FD3 signal bad. Or 27E4 not real. Or 004AFB. Match your car. Use good tool for car codes.

Tips to Stop Brake Vacuum Sensor Problems

Stop problems:

- Check hoses each year. Change if crack.

- Tune engine. Good rest means steady air pull.

- Brake soft. No hard stress.

- In hybrid, check battery. Weak hurts pumps.

- Use good parts. Cheap breaks fast.

- Park dry. No rust.

- Clean sensor spot. No dirt.

- Check air pull gauge often.

Do checks often. Parts last long.

Wrong Ideas About Brake Vacuum Sensors

- Wrong 1: Hard pedal always low brake fluid. No, often air pull bad.

- Wrong 2: Sensors never break. No, after 100k miles they do.

- Wrong 3: Drive with light on ok. No, brakes may stop bad.

- Wrong 4: Leak always gets code. No, sometimes not.

- Wrong 5: All cars same sensor. No, check your book.

Know facts. Stay safe.

Tips for Cars

- BMW MINI: In 3 series common. Check stop start off. Codes 2FD3 here.

- VW Audi: Sensor in hose. Hiss means leak.

- GM Chevy: Scan live air. 15-20 inHg good.

- Ford: Hybrid pumps electric. Fuse first.

- Toyota Honda: Not often bad. But check MAP match.

- Mercedes: Electric pump common. Check battery.

- Hyundai Kia: Sensor cheap. Change easy.

See service book always.

Conclusion

The brake vacuum sensor signal is very important. It makes sure power brakes work well. It helps start/stop systems, ESC, and ABS work right. The sensor watches booster vacuum all the time. This lets the car computer keep brake help the same in all driving conditions.

When the sensor, wires, or vacuum parts fail, clear signs show up. Hard brake pedal. Warning lights on. Longer stop distance. Special OBD codes. These problems need quick fix.

Good check uses scan tools for live data, oscilloscope for waveform, vacuum gauge, and leak tests. This finds the real problem fast.

Fix or change bad parts right away. This brings back full brake power. It stops safety danger. Check vacuum hoses, electric plugs, and sensor often. Do this more in old cars or hybrid cars. This is good preventive care. It keeps brakes safe and strong for long time.

If you see any bad signs in this guide, get a professional check fast. This makes sure your brake system stays safe and works good.

Related FAQ's

To check brake booster vacuum, use a vacuum gauge. Disconnect the hose at the booster, connect the gauge, start the engine. At idle you should see 15–22 inHg (steady). Pump the pedal several times – vacuum should hold. Low or dropping reading means a leak.

In BMW 3 Series (especially F30/F31/G20 with start/stop), the brake vacuum sensor monitors booster vacuum for power assist and auto start/stop. Common failure causes hard pedal, warning lights, and codes like 2FD3 or 004AFB. Test with ISTA scan tool; replacement often costs $150–300 including labor.