Ever tried to push a car that’s in neutral? It’s a workout. Now, imagine trying to stop that same car using only your leg. Without a vacuum power brake booster, every stoplight would feel like a leg press at the gym. This part is the "silent partner" under your hood that makes driving safe and easy.

If your brake pedal suddenly feels like a block of wood, or if you hear a strange whistling sound under the dash, your booster is probably on its way out. We have this guide that explains how they work and shows you how to test yours in your own driveway.

What is a Vacuum Power Brake Booster?

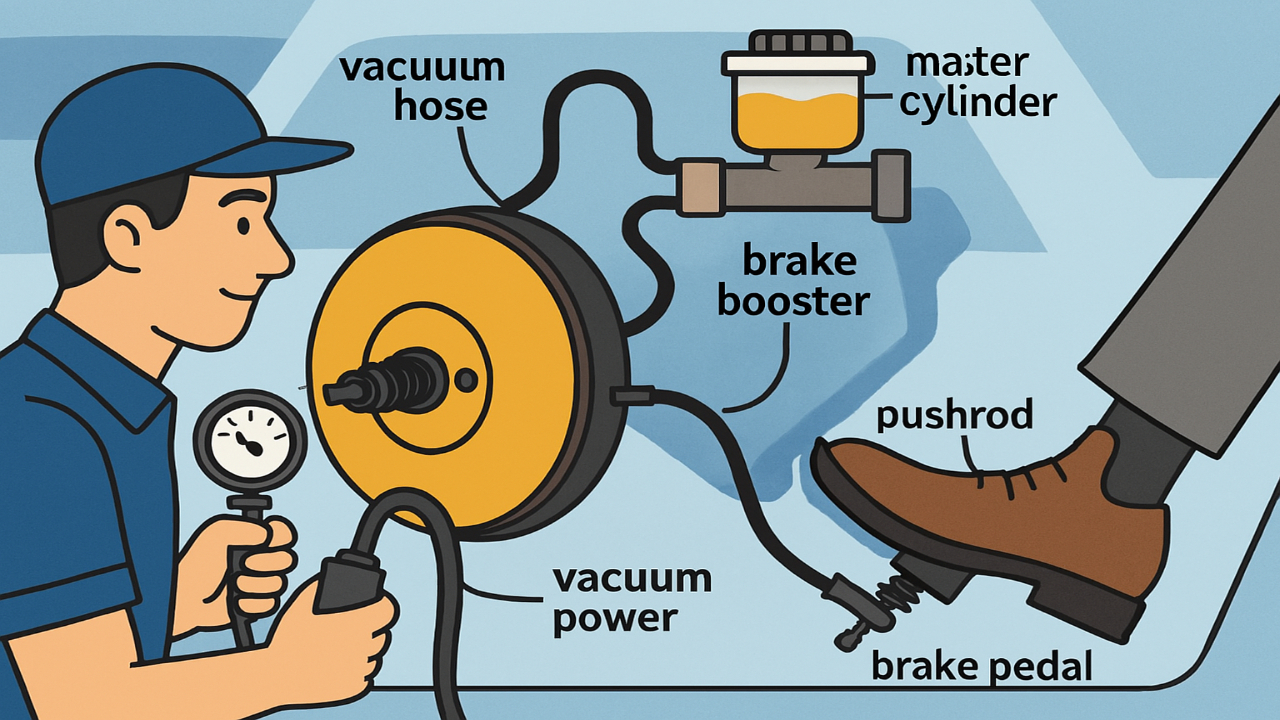

The brake booster is that big, round, black metal drum in your engine bay. Usually, it's bolted to the firewall right in front of the driver’s seat. It sits right between your foot pedal and the master cylinder.

Its main job? It’s a force multiplier. It uses engine suction to help you stop a heavy car with just a light tap of your toe. Without it, you’d have to stand on the pedal with both feet just to slow down at a red light.

Why is it there?

Cars are very heavy. When they move fast, they have a lot of energy. Your leg is not strong enough to stop a 4,000-pound car quickly on its own. The booster acts like a helper that pushes the brakes with you. It takes the small push from your foot and turns it into a giant push against the wheels.

The Science of the "Giant Lung"

A booster works because of something called pressure differential. Think of it as a giant lung that helps your leg push the brakes.

Inside the Drum

The metal canister has a flexible rubber wall inside called a diaphragm. This wall splits the unit into two rooms:

- The Vacuum Side: This side hooks up to the engine. The engine acts like a vacuum cleaner and sucks the air out.

- The Atmospheric Side: This side is near your feet. It stays sealed tight until you actually hit the brakes.

How it Moves

When you aren't braking, both sides have a vacuum, so the pressure is balanced. But the moment you tap the pedal, a rod moves and opens a small valve. This lets outside air rush into the back room. That high-pressure air slams against the vacuum on the other side, pushing the master cylinder with a ton of force.

Top Symptoms: How to Tell if It’s Failing

Since the booster is tied to both your brakes and your engine, a failure usually messes with both.

- A "Rock-Hard" Pedal: This is the most typical symptom. If the vacuum help is gone, the pedal becomes very rigid and difficult to depress.

- Hissing Noises: Hear a "shhh" sound when you slow down? That’s air leaking via a hole in the rubber diaphragm.

- Engine Trouble: A leak here is a "vacuum leak." It makes the engine run rough, shake at idle, or even stall when you come to a stop.

- Longer Stops: Because you can’t push the brakes hard enough, it takes way more distance to stop.

- Lazy Pedal: If the internal spring snaps, the pedal might stay on the floor or crawl back up very slowly.

Different Styles of Boosters

Cars don't all use the same setup.

- Single Diaphragm: Just one rubber wall. Simple and found in small cars.

- Tandem (Double) Diaphragm: Two rubber walls for double the power. You'll find these in heavy trucks and big SUVs.

- Electric Pumps: Modern EVs and some turbo cars don't have enough engine vacuum. They use a small electric motor to create the suction instead.

Quick Driveway Tests

Want to check it yourself? Try these simple tricks:

Test 1: The Pump Test

With the engine off, pump the brakes 5 times until the pedal feels like a rock. Hold your foot down and start the car. The pedal should sink slightly. If it stays hard, the booster is likely dead.

Test 2: The Check Valve

Pop the plastic elbow (check valve) out of the booster. Blow into the side that goes to the booster. Air should stay put. If you can blow air through it, the valve is toasted.

Test 3: The 30-Second Hold

Run the engine for a minute, then shut it off. Press the brake and hold it for 30 seconds. If the pedal pushes back against your foot, you have a slow air leak.

Test 4: The Hose Check

Look at the thick rubber hose. Is it cracked? If it feels "mushy" or soft, it might be collapsing when the engine is running.

Test 5: The Soap Bubble Trick

Spray some soapy water on the hose and the valve while the engine is running. If you see bubbles or hear a "slurping" sound, you've found your leak.

Why Do They Break?

- Old Age: Rubber gets dry and cracks after about 10 or 15 years.

- Fluid Leaks: If your master cylinder leaks, brake fluid gets into the booster. This fluid "eats" the rubber inside.

- Heat: Being near a hot engine makes the plastic parts brittle.

- Bad Oil: Sometimes engine oil leaks into the vacuum line and rots the seals.

Useful Parts to Know

- The Pushrod: This is the metal stick that goes from the booster into the master cylinder. If it is too short, your brakes will feel late. If it is too long, your brakes will drag.

- The Grommet: This is the rubber ring that holds the check valve. If it rips, the booster loses its air.

- The Air Filter: There is a tiny filter where the rod enters the cabin. If it gets clogged with dust, the booster works slowly.

The Cost of Fixing It

You can't really "fix" a booster. They are sealed shut and have a very strong spring inside that can be dangerous. You have to swap the whole unit.

| Item | What it Costs |

| New Part | $100 – $350 |

| Labor (1.5 to 3 hours) | $150 – $400 |

| Total Bill | $300 – $750 |

Maintenance for a Long Life

- Watch for Wet Spots: If you see fluid where the master cylinder meets the booster, fix it fast before it ruins the rubber.

- Change Your Fluid: Flush your brake fluid every 2 years to keep the seals from getting gunky.

- Keep it Clean: Don't let mud or gunk clog up the small air filter near the pedal rod.

- Check the Hoses: Every time you change your oil, look at the vacuum hose to make sure it is still flexible.

Conclusion

Getting to know your vacuum power brake booster is a smart move for any driver. These parts usually last a long time, but age and leaks eventually catch up to them. If you stay alert for a stiff pedal or weird noises, you can catch a problem before it becomes a real danger.

In the end, a good booster makes driving better and keeps your stopping power strong when it matters most. If your tests show a failure, don't wait - get it swapped out to keep your car safe.

Related FAQ

The power brake booster vacuum hose connects the engine's intake manifold to the brake booster, supplying vacuum power for easier braking. A cracked or leaking hose causes hard pedal feel and reduced stopping power - check and replace it regularly for safety.

The electric vacuum pump for power brake booster provides reliable vacuum assist when engine manifold vacuum is low - like with big cams, turbos, or modern efficient engines. It runs on 12V, activates automatically for consistent, firm braking feel and safety - quiet, efficient upgrade over traditional sources.

Aftermarket vacuum booster brake pump delivers consistent vacuum for firm brakes in modified engines - quiet, reliable 12V upgrade.