Using a high-temperature epoxy like JB Weld for a cracked oil pan is a reliable temporary solution. First, thoroughly clean and degrease the area. For added durability, add a metal patch or drill crack stop to prevent the damage from spreading.

This is an affordable, temporary repair that makes a vehicle easier to drive. Hopefully, you understand a little about epoxy, but knowing just this won’t do, so let’s go into more detail.

Understanding Your Oil Pan and the Nature of the Leak

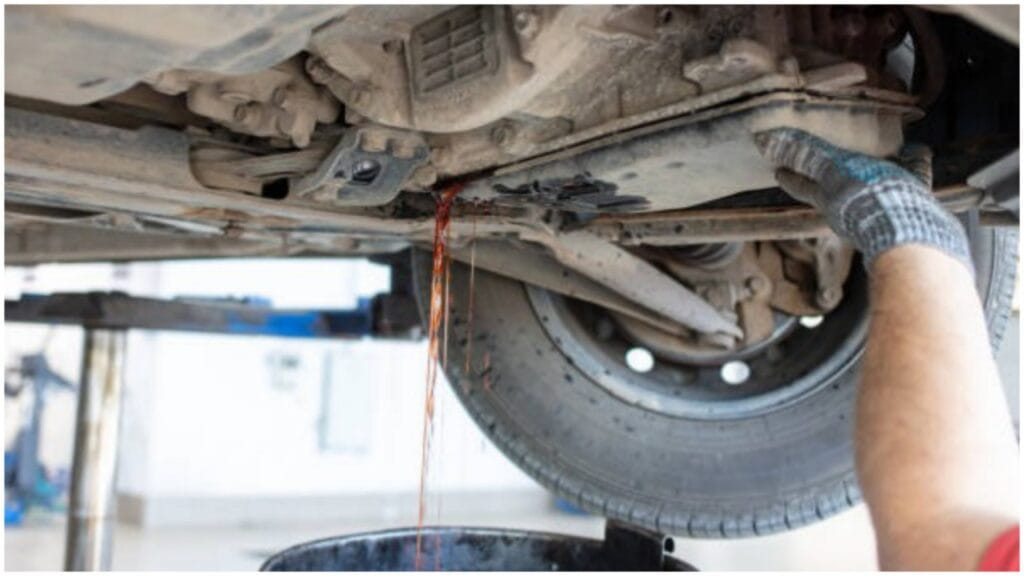

Understanding your oil pan is important to get rid of any leaks. A cracked pan or loose drain plug can cause this. Finding the exact leak location is crucial. While a temporary epoxy repair may save your engine, it is not a permanent solution. This temporary repair may give you some time to make a proper, permanent repair.

Identifying the Type of Oil Leak

Identifying oil leaks requires keen observation. You can often pinpoint the source by checking the color and location of the fluid. A dark, blackish fluid is usually engine oil, while reddish fluid is often transmission fluid. You can also use a UV dye and blacklight to trace the leak’s path.

Oil Pan Material Matters: Aluminum Pan vs. Steel Oilpan

Steel oil pans are tougher, less prone to cracking from impacts, and are often cheaper. However, they can rust. Aluminum pans are lighter and dissipate heat more effectively, which can help cool engine oil. Unlike steel, they are more brittle and prone to cracking upon impact, making them harder to patch.

What epoxy works with oil?

JB Weld is the go-to choice. It’s a specialized, steel-reinforced epoxy putty that handles high temperatures and chemicals. The absolute key is this: no epoxy will stick to oil. You must perfectly clean, degrease, and sand the repair area before you apply the epoxy for a permanent bond.

Key Properties for Oil Pan Repair

Epoxy for oil pan repair needs three key properties. It must be high-temperature resistant to handle engine heat. It needs chemical resistance to withstand motor oil.

Most uniquely, it must have high shear strength and adhesion to create a durable, permanent bond on a metal surface, preventing further leaks.

Understanding Two-Part Epoxy Systems

Two-part epoxy is typically made with a resin and a hardener. When you mix them, they don’t dry; a chemical reaction begins. This process, known as polymerization, creates a new, incredibly tough plastic.

It creates a permanent, high-strength bond that’s much stronger than regular glue. This makes it ideal for durable repairs on stressed parts like oil pans.

How to Choose the Right Epoxy for Your Repair

Choosing the right epoxy is crucial to success. You must choose a product specifically formulated for automotive use. It must be steel-strengthened to form a strong bond with the metal. The epoxy must withstand the high temperatures of the engine and the corrosive nature of motor oil.

A unique tip: Look for a two-part epoxy putty stick. Unlike liquid adhesives, the putty can be kneaded and physically forced into a crack. This unique application creates a deep, solid plug that fills the void, ensuring a more effective and durable seal against pressure. Some of the ways to do this are detailed below.

Matching Epoxy to Your Oil Pan Material

Matching epoxy to your oil pan is critical. For steel pans, a standard steel-reinforced epoxy is ideal. It bonds strongly to steel’s robust surface. Aluminum pans are different. A unique challenge is that they dissipate heat so quickly, affecting the epoxy’s cure time.

For these, use an epoxy specifically for aluminum. This ensures the bond handles thermal stress. Always pick a product rated for both your pan’s material and high heat.

Considering the Leak Type and Size

How you fix the pan depends on the damage. For a tiny pinhole, just a dab of epoxy putty is often enough. For a crack, a unique but crucial step is to drill a small hole at each end.

This stops the crack from spreading. For a larger hole, simply patching it won’t hold. You must use a reinforcing metal patch over the epoxy for a true, strong structural repair.

Temperature Resistance

For oil pan repair, temperature resistance is essential. Engine oil gets very hot, so a standard epoxy won’t last. You must use an epoxy rated for high heat, typically 250°F or more.

A unique detail is that this high-temp rating also helps the epoxy cure faster and stronger. The elevated temperature from a running engine helps solidify the bond, turning a temporary fix into a more durable one.

When NOT to Use Epoxy on an Oil Pan

Using epoxy is not always the best idea. You should avoid it when the oil pan has major structural damage like a large dent or a tear. Epoxy is a patch, not a structural repair. Never use it on a stripped drain plug thread.

While some people try, it’s a dangerous, unreliable fix that can fail and ruin your engine. Also, don’t use it as a substitute for a missing gasket or on a leaking seam. For these unique issues, the only correct fix is to replace the pan or its gasket.

Oil Pan Repair vs. Replacement: What’s the Right Choice?

The right choice depends on your situation. The simple truth is that an epoxy repair is a temporary fix. It is only for a small leak or a tiny crack. It’s a quick, cheap solution. An epoxy patch can fail unexpectedly. Think of it as a bandage for your car.

A full replacement is the only reliable choice. It costs more money. It takes more time. But it removes all risk of failure. The right choice depends on your car’s future. An epoxy repair is for emergencies or for a car you are selling. A replacement is for any vehicle you plan to keep long-term.

FAQ’s

Can you seal an oil leak from the outside

Yes, you can seal an oil leak from the outside. The method uses a specialized two-part epoxy or a steel-reinforced putty. It is a common roadside emergency fix. But a unique, and crucial, point is that success depends entirely on one thing: surface preparation.

You cannot simply apply it over a leaking area. If any oil or grease is left, the epoxy will not stick. It will fail, often very quickly. You must first thoroughly clean and degrease the entire area.This kind of outside repair also only works for specific leaks. It is effective for small cracks or pinholes on a solid part like an oil pan.

It will not work on a leaking gasket, a loose bolt, or a leaking seal. These issues require a mechanical repair, not a patch. So, while you can seal an oil leak from the outside, it is a temporary bandage for a specific type of damage.

How to stop oil pan gasket leak?

You cannot stop an oil pan gasket leak with an outside patch. The simple truth is that it will not work. A unique reason why is that gaskets are designed to be flexible. They compress to form a seal and they move with the expanding and contracting metal of your engine.

A rigid patch like epoxy cannot handle this movement. It will simply crack and fail almost instantly. A dangerous mistake people make is to overtighten the bolts, thinking it will stop the leak. This can crush the gasket and cause it to leak even more.

It can also strip the threads in your engine block, which is a much bigger problem. The only correct solution is to replace the gasket. This involves removing the pan and carefully cleaning both surfaces to ensure a perfect seal with the new gasket.

How to fix a leaky oil pan

To fix a leaky oil pan, you must first identify the source of the leak. If the pan itself has a crack or pinhole, you can apply a temporary patch with a high-temperature epoxy. The unique key to a successful epoxy repair is meticulous surface preparation; the area must be perfectly clean and free of any oil for the epoxy to bond.

However, if the leak is coming from the gasket, which is the flexible seal between the pan and the engine, you cannot use an external patch. A unique reason for this is that a gasket is designed to expand and contract with engine heat, and a rigid patch would simply crack and fail. In that case, the only correct and permanent fix is a complete gasket replacement.

Cracked oil pan replacement

When you have a cracked oil pan, replacement is the only reliable, permanent fix. While a temporary patch with epoxy can buy you time to get to a repair shop, it’s not a true solution. The unique information about oil pan replacement is that it’s often more than just a simple bolt-on job. You have to ensure that you are replacing the pan with the correct part that matches your engine’s oil pickup tube and other internal components.

Additionally, the process requires draining all the old oil, removing the old pan, cleaning the engine’s mating surface completely, installing a new gasket, and finally bolting on the new pan with precise torque. This ensures a leak-proof seal and long-term durability, something an epoxy patch can never guarante.

Conclusion

A leaky oil pan demands a two-part solution. For a cracked pan, a temporary epoxy patch is possible, but its success hinges on meticulous surface preparation. A unique detail is using stop-drills to prevent cracks from spreading.

For a gasket leak, a patch is useless; the gasket’s designed flexibility makes it incompatible with rigid epoxy. The only permanent fix is replacement, but the unique challenge is ensuring perfect surface cleanliness and using the correct torque to avoid future leaks or stripped threads.