Finding the best sealant for a valve cover gasket depends on your needs, but RTV silicone sealants are a top choice. RTV stands for “Room Temperature Vulcanizing,” meaning it cures quickly and seals tightly.

It’s heat-resistant, oil-proof, and creates a strong bond, making it ideal for engine parts. One reliable option is Permatex Ultra Black or Ultra Grey. These sealants are designed to handle high temperatures and resist oil exposure, ensuring your valve cover stays leak-free. Let’s know more about it.

Why Sealant Even Matters

A valve cover gasket alone doesn’t always do the trick. Sometimes, the surfaces it’s supposed to seal aren’t perfectly aligned or smooth.

That’s where sealants come to the rescue, filling those tiny gaps and ensuring a leak-free fit. Thus, they are essential.

Choosing Your Ally

Some sealants are suitable for a valve cover gasket. Silicone-based options, especially RTV (Room Temperature Vulcanizing) sealants, are the best. They’re flexible, heat-resistant, and stick like glue—but not severely.

Then there are anaerobic sealants. These are perfect for metal-to-metal surfaces but might not be ideal for all valve covers. Some brands make hybrids, which blend the best of both worlds.

The type you choose depends on your engine and the material your valve cover is made from.

My Personal Favorite

If I had to pick one, it’d be Permatex 85084-6PK Ultra Grey Rigid High-Torque RTV Silicone Gasket Maker. It’s oil-resistant, can handle high temperatures, and doesn’t shrink.

The Prep Work Is the Key

A clean surface is your best friend here. Any remaining oil, grime, or old gasket material can cause further damage.

I like to use a degreaser to clean the mating surfaces. Brake cleaner also works, but make sure everything’s dry before applying the sealant.

Speaking of old gasket material, don’t rush the scraping part. Use a plastic scraper to avoid scratching the metal.

Applying Sealant: The Right Way

A thin, even bead along the edge of the valve cover does the trick. Too much and excess squeezing will occur, which can damage the engine.

Suppose you’re using RTV; skin over it for a few minutes before pressing the gasket into place. Some sealants require longer curing times, so always check the instructions.

And don’t tighten the bolts just yet! Most sealants need time to cure before you torque things down.

Torquing Down the Cover

Speaking of torque, precision matters here. Overtightening can distort the gasket or damage the valve cover. I like to use a torque wrench for this.

It might seem excessive, but it ensures you’re not putting too much pressure on one side. Tighten in a crisscross pattern to distribute the load evenly.

Waiting Game

Sealants need time to cure fully before they’re exposed to oil or heat. I usually wait 24 hours, even if the packaging says it’s good to go in a few hours. It’s just a precaution, but it’s served me well.

Testing the Waters

Once everything’s cured and tightened, it’s time to start the engine. Watch for leaks, and don’t panic if you first see a tiny bit of oil. Sometimes, it’s just residue from the old gasket. Wipe it clean and keep monitoring.

Common Pitfalls to Avoid

Here’s a quick rundown of mistakes I’ve made, so you don’t have to:

- Using too much sealant. Less is more.

- Skipping the cleaning step. Always start with a spotless surface.

- Ignoring cure times. Rushing this step can undo all your hard work.

- Tightening bolts unevenly. Precision is key here.

Compatibility Is Key

Not all engines are created equal. Some need specific sealants to match their unique quirks. It’s not just about temperature resistance, though that’s a big deal. It’s also about chemical compatibility.

For instance, oil-resistant sealants are necessary for any job involving valve covers. Oil will quickly break down a standard adhesive, leaving an even worse leak.

Knowing When To Skip It

Not every valve cover gasket needs a sealant. Some modern engines use gaskets designed to work without it.

These are typically made of advanced materials like rubber or metal and have built-in ridges that automatically create a tight seal.

Adding sealant here could backfire, causing uneven pressure or unwanted residue.

Sealants for Different Materials

Did you know that the material of your valve cover affects the type of sealant you should use?

Metal valve covers, for example, often work best with high-temperature RTVs, like copper or aluminum-colored formulas.

Plastic valve covers, on the other hand, are more forgiving but still need something flexible and heat-resistant.

The Right Tools for the Job

A good sealant application isn’t just about the product and the tools you use. They let you control the bead size and reach into tricky corners.

A simple popsicle stick can also work wonders for spreading and smoothing sealant evenly.

Temperature Extremes

Engines run hot, no doubt about it. But how hot it is depends on the make and model. Some sealants handle extreme temperatures better than others.

If you’re dealing with a high-performance or turbocharged engine, you’ll want a sealant rated for higher temps.

Overlooked Areas

Everyone focuses on the edges, but don’t forget the valve cover’s corners and curves. When leaks appear, these spots are the usual suspects.

I always add a tiny dab of sealant in these trouble zones, even if the gasket looks snug. It’s a small step that prevents big problems later.

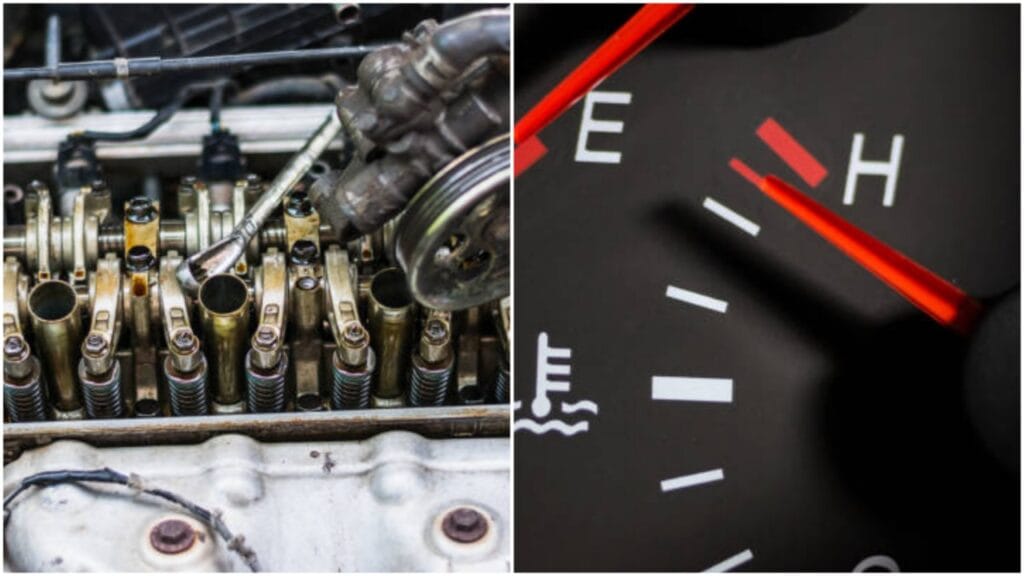

The Role of Sealant in Preventing Engine Damage

Bad oil doesn’t just stain your driveway—it can seriously damage your engine. Oil dripping onto components like alternators or belts can shorten their lifespan.

Worse, oil pooling near the exhaust manifold can pose a fire risk. Using the proper sealant isn’t just about stopping leaks; it’s about safeguarding the health of your engine. Plays many vital roles.

When Heat and Pressure Combine

Engines are like pressure cookers, constantly cycling through heat and force. Without the proper sealant, even the best valve cover gasket can fail.

I’ve noticed this, especially in older vehicles where parts aren’t as perfectly machined—the sealant cushions absorb the stresses that would otherwise cause leaks.

Don’t Forget the Bolt Holes

It’s easy to focus on the edges of the valve cover gasket, but those bolt holes can be sneaky culprits. If they aren’t sealed properly, oil can seep out through the threads.

I always apply a tiny dab of sealant to the bolt threads before tightening them down. It’s a simple step, but it makes a world of difference.

DIY or Let the Pros Handle It?

Not everyone feels comfortable working on their engine, and that’s okay. Applying sealant might seem intimidating if you’re new to DIY car repair.

But here’s the thing: it’s one of the more approachable tasks. With the right tools and a bit of patience, you can do it yourself.

Calling a pro might be better if the leak is in a hard-to-reach spot or part of a bigger problem.

Choosing Between Colors

Have you ever noticed how sealants come in different colors—black, red, grey, and even copper? Those colors aren’t just for looks; they indicate the sealant’s properties.

Black is usually the all-purpose variety, red is for high-heat applications, grey works well with aluminum, and copper is for extreme temperatures. Picking the right color can make your repair last longer.

How Humidity Affects Sealants

If you apply sealant in a humid environment, the curing process can take longer. Some sealants even react differently depending on the weather.

It’s best to work in a dry, controlled environment whenever possible.

Checking for Compatibility with Other Fluids

Engines deal with oil, coolant, fuel, and other fluids, which can degrade certain sealants over time.

It’s always a good idea to check if your sealant is resistant to all the fluids it might encounter.

Sealant’s Lifespan

Sealants don’t last forever. If you’ve had a valve cover gasket in place for years, the sealant might have degraded even if the gasket is intact.

FAQ’s

Valve cover gasket silicone!

When replacing a valve cover gasket, sometimes no additional sealant is needed. Many modern gaskets, especially those made of rubber, are designed to seal effectively on their own.

The key is to ensure the mating surfaces on both the valve cover and cylinder head are perfectly clean and free of old gasket material or oil.

Proper torque specifications must be followed precisely. Over-tightening can distort the valve cover, while under-tightening leads to leaks. A well-installed, quality gasket, without any added compounds, can provide a reliable, leak-free seal.

Can i use gasket maker on valve covers?

Yes, gasket maker works for valve covers, but for a unique tip, consider applying it only in specific problem areas. Instead of a full bead, dab a small amount at corners or where the cylinder head surface has a slight gap. This prevents over-application which can lead to sealant squeezing out and potentially clogging oil passages inside the engine.

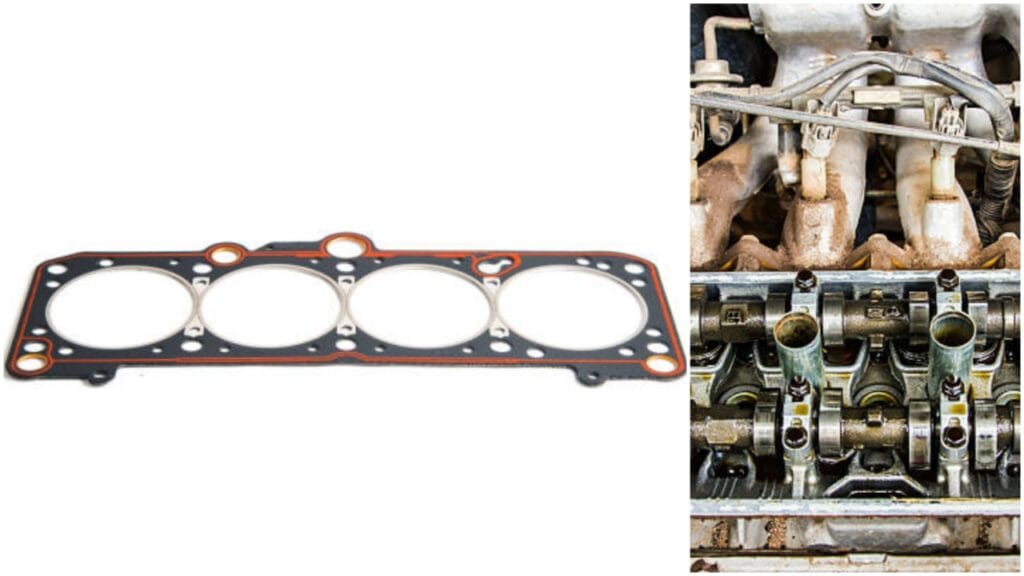

Valve cover gasket replacement sealant

For valve cover gasket replacement, sealant often plays a crucial role. While many modern gaskets are designed to seal dry, RTV (Room Temperature Vulcanizing) silicone is commonly used.

It helps fill tiny imperfections on mating surfaces, ensuring a leak-free seal. Apply a thin bead of RTV in specific areas, like corners or where different engine components meet. Always ensure surfaces are clean and dry before application.

Permatex Ultra Black or Ultra Grey are popular choices, known for oil resistance and sensor-safe properties. Always follow the specific sealant and gasket manufacturer’s instructions for best results and proper cure time.

Best gasket sealer for valve covers!

For valve covers, Permatex Ultra Black RTV is a top choice. It offers excellent oil resistance and flexibility. Apply it sparingly, typically only in the corners or stepped areas, where the molded gasket might not seal perfectly. Always ensure surfaces are clean and dry for the best seal.

valve cover gasket sealant!

Proper valve cover gasket sealant application prevents oil leaks and ensures engine longevity. Begin with meticulously cleaning both the valve cover and cylinder head surfaces, removing all traces of old gasket material and oil.

Select a high-quality, temperature-resistant RTV (Room Temperature Vulcanizing) silicone sealant designed for automotive use. Apply a thin, uniform bead of adhesive to the gasket or valve cover, paying close attention to corners, seams, and areas prone to high stress. Avoid excessive sealant, as it can squeeze into oil passages and cause blockages.

Allow the sealant to cure fully according to the manufacturer’s specified time before installing the valve cover. When tightening the valve cover bolts, follow the manufacturer’s torque specifications and use a torque wrench to prevent over-tightening, which can damage the gasket and lead to leaks. This meticulous process ensures a reliable, leak-free seal and protects the engine from oil loss and potential damage.”

What gasket maker for valve cover?

When choosing a gasket maker for your valve cover, it’s crucial to pick a reliable product that can handle the pressure and temperature of the engine. RTV silicone gasket maker is often the best option.

This type of gasket maker creates a strong, flexible seal that can withstand high heat and pressure. It is perfect for valve covers since it resists oil, coolant, and other engine fluids.

Popular brands like Permatex and Loctite offer RTV silicone gasket makers specifically designed for automotive use. They provide excellent adhesion and ensure the gasket stays intact, even under extreme conditions.

Before applying the gasket maker, ensure the surfaces are clean and dry. Any dirt or oil will prevent a proper seal. Apply the gasket maker in a thin, even layer around the valve cover. Then, carefully press the valve cover back in place.

Let the sealant cure appropriately before starting the engine. Most RTV sealants require at least an hour to set, but check the product’s instructions. A quality gasket maker can save you from leaks and expensive repairs.

Valve cover gasket leak sealer?

A valve cover gasket leak sealer can temporarily fix minor leaks when you’re not ready for a complete repair. These sealers are typically oil additives designed to condition the gasket and restore some of its elasticity.

Over time, gaskets can become brittle, causing them to shrink or crack. The sealer works by soaking into the gasket material, making it more pliable and helping it form a better seal against the engine.

If the gasket is severely damaged or the leak is too big, the sealer won’t help. It’s also not a long-term fix; you’ll need to replace and properly seal the gasket with the proper sealant.

Fel-Pro valve cover gasket, which side up?

When installing a Fel-Pro valve cover gasket, knowing which side faces up is crucial for a proper seal.

Most Fel-Pro gaskets are designed with a specific orientation, and while they may look symmetrical at first glance, they often include subtle features to indicate the correct side.

Typically, Fel-Pro gaskets have a smooth side and a textured or grooved side. In most cases, the textured or grooved side should face the valve cover, while the soft side should face the engine head.

This design helps the gasket stay seated securely in the valve cover while providing a tight seal against the engine.

Another key detail is whether the gasket includes a pre-applied bead of sealant. If it does, this bead will always face the engine side.

The gasket’s design considers the highest oil pressure, ensuring the sealant bead works where it’s needed most.

For added clarity, some Fel-Pro gaskets include printed text or directional markers indicating the correct orientation.

Fel-Pro is excellent about including detailed installation guidelines, so don’t skip that step. Proper installation prevents leaks and ensures a long-lasting repair.

A backward gasket might still fit but won’t seal properly, leading to frustrating oil leaks.

Always clean the mating surfaces thoroughly before installing the gasket. Any leftover oil or debris can prevent the gasket from seating correctly, even if facing the right way.

With the gasket aligned and the valve cover bolts torqued evenly, you’ll have a leak-free seal built to last.

Do rubber valve cover gaskets need sealant?

Rubber valve cover gaskets usually don’t need sealant, but exceptions exist. Most modern rubber gaskets are designed to seal perfectly on their own.

They are flexible, durable, and fit snugly against the valve cover and cylinder head. However, adding sealant to these gaskets can sometimes cause more harm than good.

Too much sealant can squeeze out during installation, potentially clogging oil passages or making future repairs messy.

However, certain situations may call for a small amount of sealant. If the valve cover or engine mating surface is slightly warped or has imperfections, a thin RTV silicone layer can help fill those gaps.

Sealant is also recommended in areas prone to leaks, like the corners where the valve cover meets the timing cover.

Some engines even have manufacturer recommendations for applying sealant in specific spots, so it’s always wise to check your vehicle’s service manual.

What is the best valve cover gasket sealant?

The best valve cover gasket sealant depends on your engine type, the materials involved, and the conditions it will face.

Permatex Ultra Black RTV Silicone Gasket is Very popular and effective. It’s designed for high-temperature and oil-resistant applications and is perfect for valve cover gaskets.

This sealant provides a strong, flexible bond that can withstand an engine’s heat and vibration. It’s also resistant to oil and critical for preventing leaks in this area.

For aluminum valve covers, Permatex Ultra Grey is another excellent option. It is formulated to work well with metal surfaces and provides the same durability and resistance as Ultra Black.

Some even prefer Permatex High-Temp Red RTV for extreme heat conditions, such as high-performance or turbocharged engines, but it may not be necessary for standard engines.

Anaerobic sealants, like those from Loctite, can also be ideal for metal-to-metal sealing applications. These dondon’trdendo do not dry until deprived of air, making them great for tight spaces where precise sealing is essential.

While these are all fantastic choices, the “be” t” s” plant also depends on whether your gasket needs it. Modern rubber gaskets are often designed to seal without additional help.

Always check your recommendations. Using the wrong sealant—or too much of it—can lead to problems like clogged oil passages or uneven sealing.

Conclusion

Fixing a valve cover gasket isn’t rocket science but requires attention to detail. The proper sealant can make all the difference, turning a leaky mess into a reliable seal.

Whether you’re a seasoned mechanic or a weekend DIYer, taking the time to do it right will save you a ton of headaches down the road.

With the proper sealant, a steady hand, and patience, that engine will run clean quickly.

Let me know if you need more ideas or want me to expand on anything else!